Jining Genying Machinery Co., ltd is a top professional producer of undercarriage parts which developed by the experienced engineers. Specializing in the production of a variety of undercarriage parts, sidewalks (road), drive shaft assembly and other products for more than 20 years. Our products are based on our clients need. We can offer the products of famous brand like, XCMG, Caterpillar. Through serving our clients with the best, we have gained our trust and are now rewarding it through exporting to over 10 countries proving that we are a reliable supplier in industry.

Why Segments Matter to Your Sprocket Performance

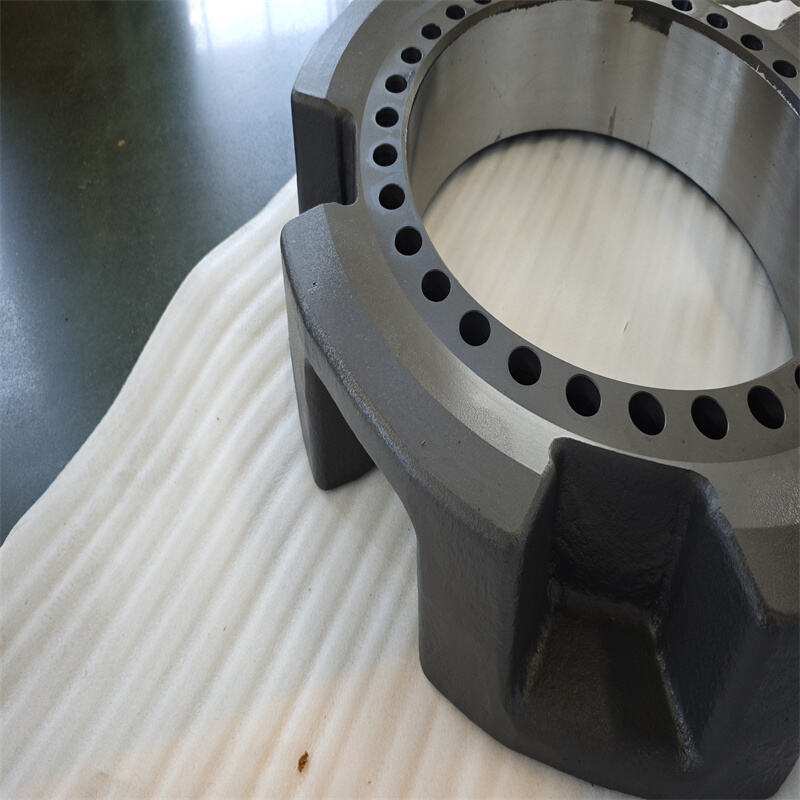

Sprockets are an important part in construction machinery, which need high smooth and reliable drive from the engine to work with different ground. Segments are parts of the Sprocket that affect the equipment's overall performance and longevity. The loading on each part is reduced by segmenting the sprocket through load sharing. Force is thus distributed and the sprocket operates more effectively over a longer period, which can increase machine’s performance life and production.

What Segments Can Do for You Wholesale Purchase?

When looking to buy segments on wholesale or construction machinery parts and sprockets, you should know how these attachments will be able to increase the overall value and quality of your product. Sectional sprockets benefit in customization and flexibility Sections can be interchanged separately without the need to change the whole unit. This affordable solution will not only cut down on replacement costs, but also downtime, making it more efficient and saving wholesale buyers a large sum of money.

Optimizing Segmented Sprocket Technology

Simply by applying the segmented crawler crane drive sprocket technology to a construction machine vantages you with increased capacity, longer service life and lower maintenance costs. Segmented sprockets enable the design to be tailored for specific operating conditions such as different load capacities or terrain types. This flexibility enables organizations to optimize the performance of their equipment resulting in superior results at difficult work sites while reducing maintenance costs which maximizes bottom-line profitability.

Effects of Segments on Sprocket Lifetime and Durability

A major advantage of splined sprocket is, however, that they have a positive effect on the wear and lifetime of construction machinery. By distributing the work load over a number of regions, wear on any one portion is minimized and the overall life of the sprocket is extended. This stronger construction material means that machinery will last longer, and you won't need to replace it as often, leading to less downtime and fewer expenses for your business in the long run.

Increasing Profit Margins with Sprocket Segmented Solutions

In the construction machinery industry, fierce competition exists, and enterprises are always exploring various means to improve profits and maintain competitive advantages. Modular sprocket solutions represent a strategic opportunity to get further in this pursuit, especially cost effective and efficient maintenance and operation. Through application of segmental sprocket technology, companies have the capability of enhancing equipment performance and minimizing maintenance costs and improving productivity translating into greater profitability over time in a competitive market.